TWB COMPANY

PROCESS

Superior Solutions from Start to Finish

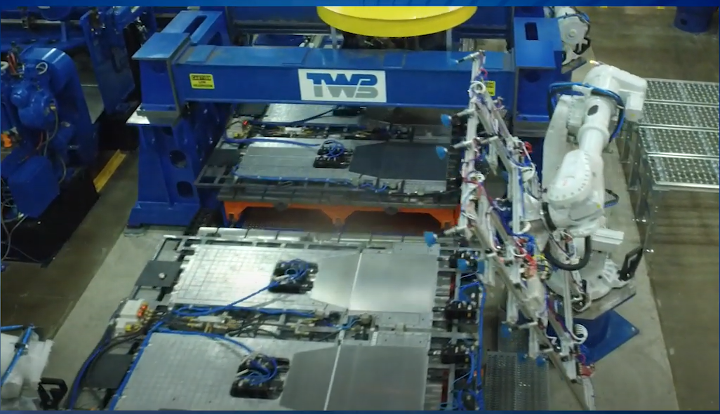

Tailor welded products reduce weight, lower cost, improve material utilization, consolidate parts and upgrade performance.

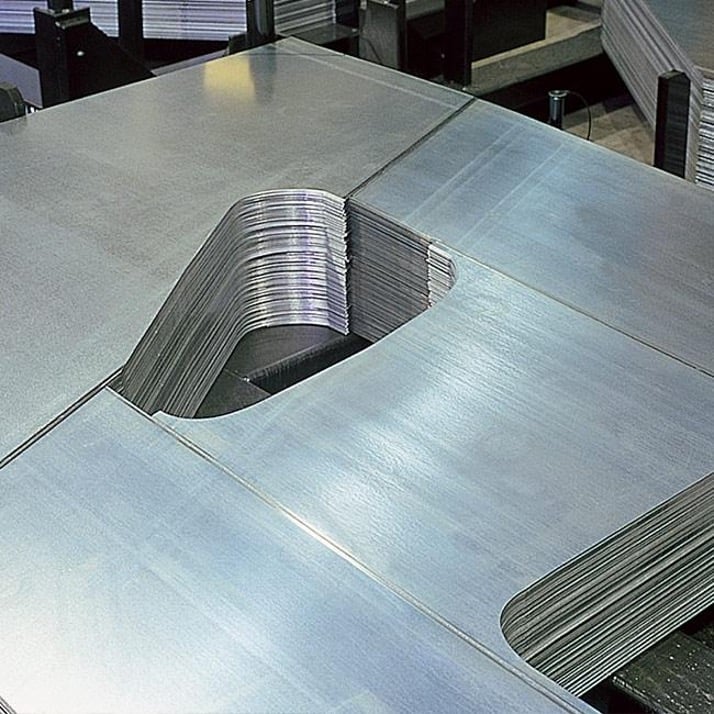

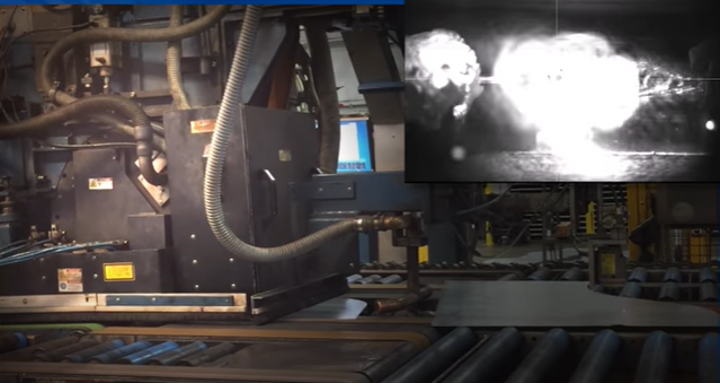

It starts with individual steel or aluminum sheets of different thickness, strength and coating, which are then joined together by laser welding. This produces a single welded blank panel that can be stamped or formed into a finished part.

The resulting products provide TWB’s customers with cost-effective, lightweighting solutions that deliver unmatched performance, strength and durability to meet the fuel economy, range and safety requirements of today and the future.

Better Components. Better Value. Better for the Planet.

Driving Progress with Uncompromising Quality

Product Development

A Trusted Ally for Innovative Solutions

Customers rely on TWB for proactive support at every stage of new product development. Their expertise helps design solutions that reduce material cost and weight and improve quality and performance while optimizing production processes.

Wherever steel and aluminum are used, tailored products can improve results. Beyond automotive applications, TWB’s solutions can power innovation for industries such as alternative energy, appliance, trucking, rail car, shipbuilding, construction, trailer, elevator/escalator, and furniture.